|

• CLI-1D is developed for high duty, oil lubricated, hydraulic applicaations;

• CLI-1D is with excellent wear resistance and low static and dynamic frication coefficient, special stuitable for frequently reciprocating motion;

• CLI-1D is with or without the strong stocks from side directions;

• CLI-1D parts also know as SF-1D or similar to DP4 .

TECHNICAL DATA

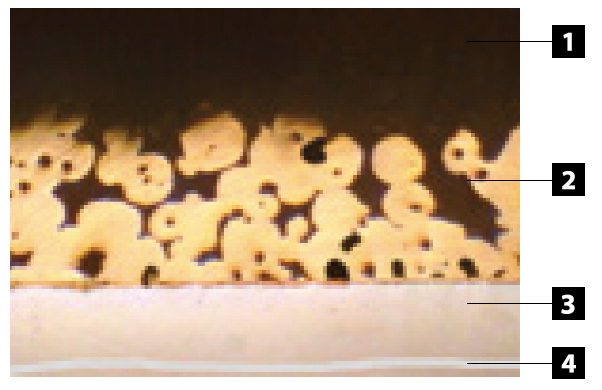

| • Metallographic Micrographs |

|

|

• Technical Data |

Layer 1: PTFE mixed with Polymer Fibers, thickness 0.01 to 0.03 mm

Layer 2: Sintered bronze powder, thickness 0.20 to 0.35 mm

Layer 3: Low carbon steel backing, thickness 0.70 to 2.30 mm

Layer 4: Copper or Tin coating, thickness 0.008 mm

♦ The actual thickness of metallographic structure as the negotiation |

|

|

| Items |

Value |

Unit |

| Maximum Operating Temperature Tmax |

280 |

°C |

| Minimum Operating Temperature Tmin |

-200 |

°C |

| Maximum Static Load Psta,max |

250 |

N/mm2 |

| Maximum Dynamic Load Pdyn,max |

140 |

N/mm2 |

| Maximum Sliding Speed V-dry |

2.5 |

m/s |

| Maximum Sliding Speed V-oil lubricated |

5 |

m/s |

| Maximum PV Factor-dry |

1 |

N/mm2 * m/s |

| Maximum PV Factor-oil lubricated |

10 |

N/mm2 * m/s |

| Coefficient of friction f-dry |

0.04-0.25 |

| Coefficient of friction f-oil lubricated |

0.02-0.08 |

| Usage |

dry |

good |

| oil lubricated |

very good |

| grease lubricated |

good |

| water lubricated |

fair |

| process fluid lubricated |

good |

|

|

APPLICATIONS

1. PTFE and Polymer Fibers created the lubricated film and it is transfered to teh mating shaft to improve running properties, also protect the mating surface of shaft;

2. Perfect wear resistant, lower friction, suitable for the working conditions of with or without lubricating oil, and keep the lubricating oil clear after long period of working;

3. Particularly suitable for bushes in reciprocating motions, also for other motions;

4. Used in automotive suspension structs, shock absorbers, hydraulic, cylinders, gear pumps, motors, axial and radial pistion pumps & motors. |

|

|

|

|

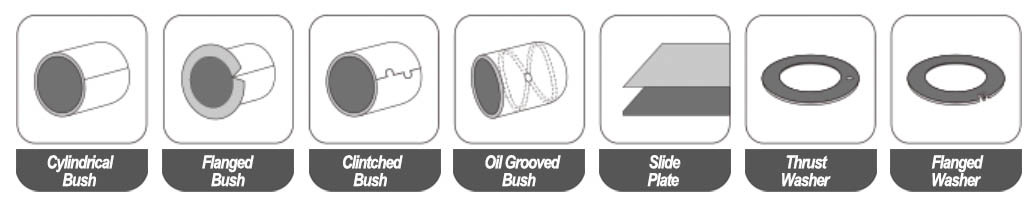

STANDARD TYPES AVAILABLE

Plese select the bearings in the following tables. Click " CLI BEARING NO. " or " DETAILS " to check the specifications...

|